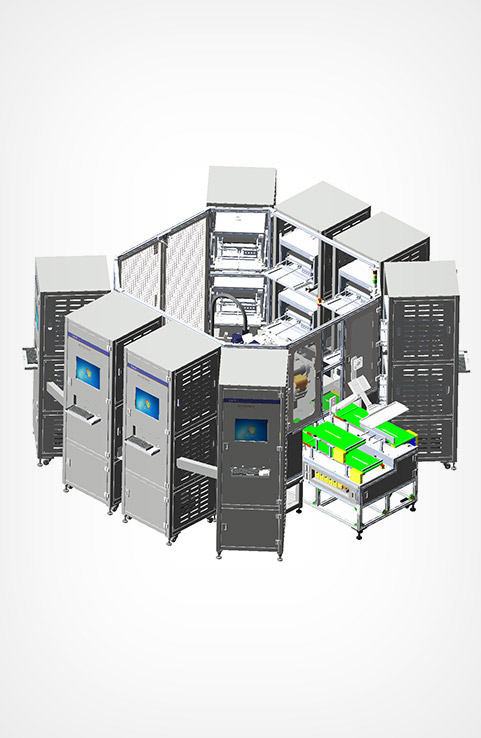

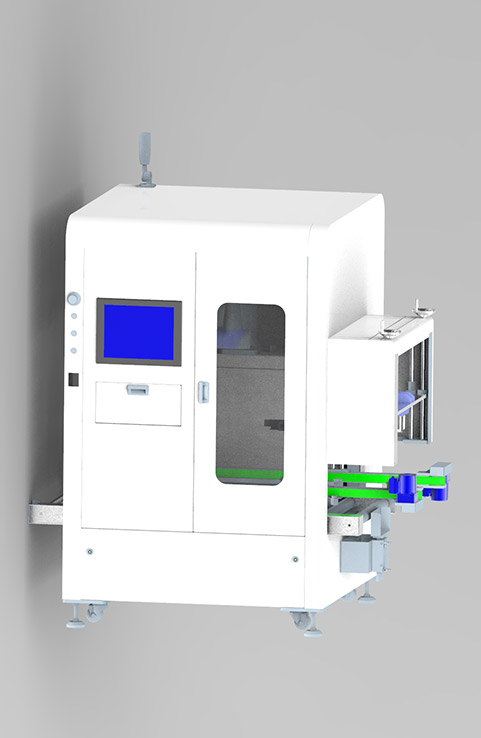

Independent shielding box test cabinet

Simultaneously supporting 16 channel shielded box testing

Closed design

Manpower reduction: 3 → 1 person

High space utilization and scalability

The whole machine is anti-static, safe and reliable

Supports both offline and online functions

Support data exchange between MES and other production systems

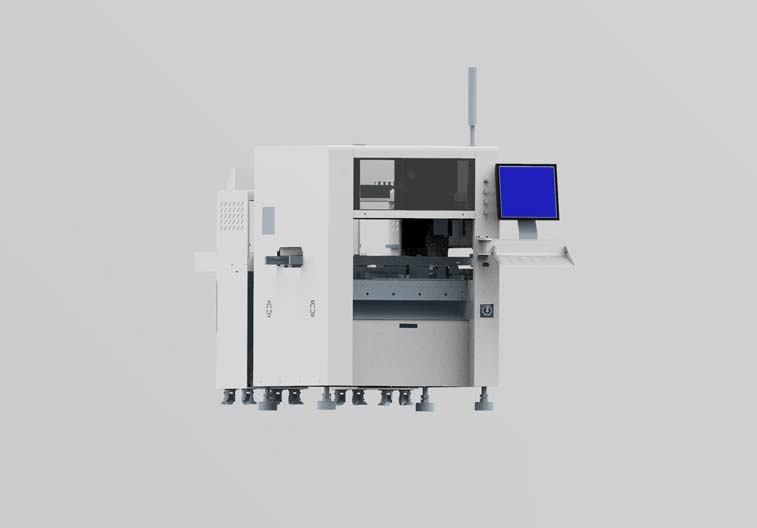

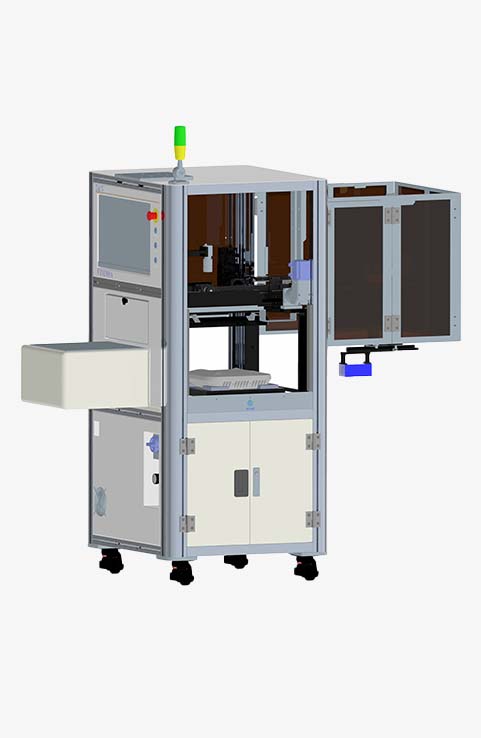

Dual platforms support two products simultaneously

Low cost, simple and convenient operation

Adopting multiple detection and motion control technologies

Support data exchange between MES and other production systems

Import servo electric batch and display torque in real-time

Supports multiple products and screw specifications

The whole machine is anti-static, safe and reliable

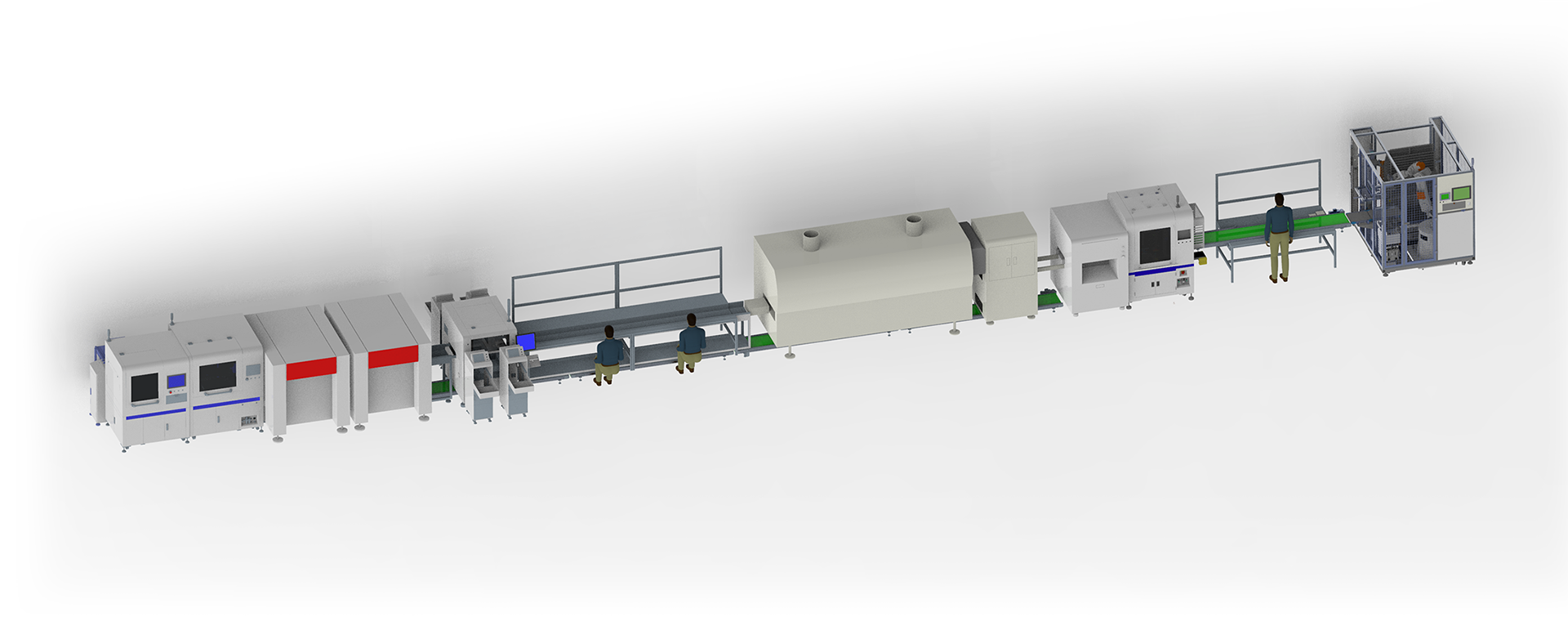

The whole machine adopts a modular design concept

Automatic loading and unloading components can be added according to demand

The automatic labeling machine supports two products on both platforms simultaneously

Supports multiple products and screw specifications

Automatic cutting and flipping, capable of locking screws on both sides

Adopting multiple detection and motion control technologies, the operation is simple and convenient

Support data exchange between MES and other production systems

Servo electric screwdriver, real-time display of torque

The whole machine adopts a modular design concept

The whole machine is anti-static, safe and reliable

Dual platforms support two products simultaneously

Low cost, simple and convenient operation

Adopting multiple detection and motion control technologies

Support data exchange between MES and other production systems

Supports multiple barcodes

The whole machine is anti-static, safe and reliable

Reduce the error rate of manual packing

Supports both offline and online functions

Equipped with automatic loading and unloading functions

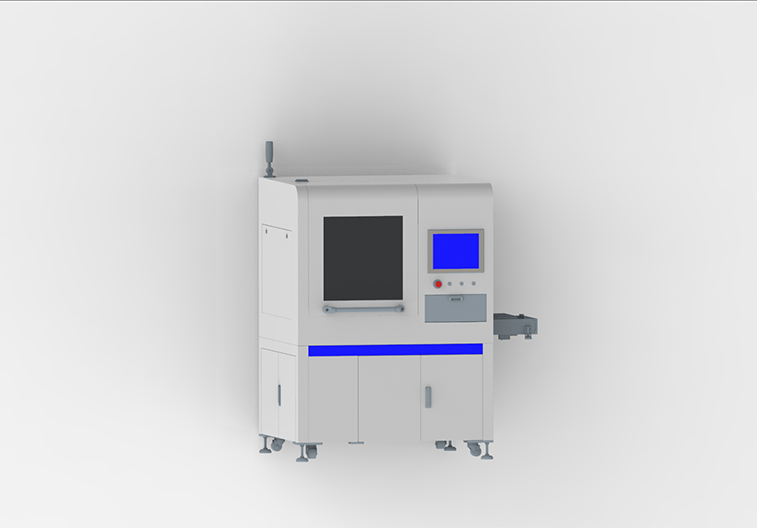

Equipped with front and back double-sided inspection function

Check the correctness of the screen printing on the surface shell [yes/no]

Label inspection

Record the inspection results, read the barcode and upload it to MES

Support data exchange between production systems such as MES

Detection efficiency: UPH ≥ 300PCS/h

Store at least 500 sets of product formulas

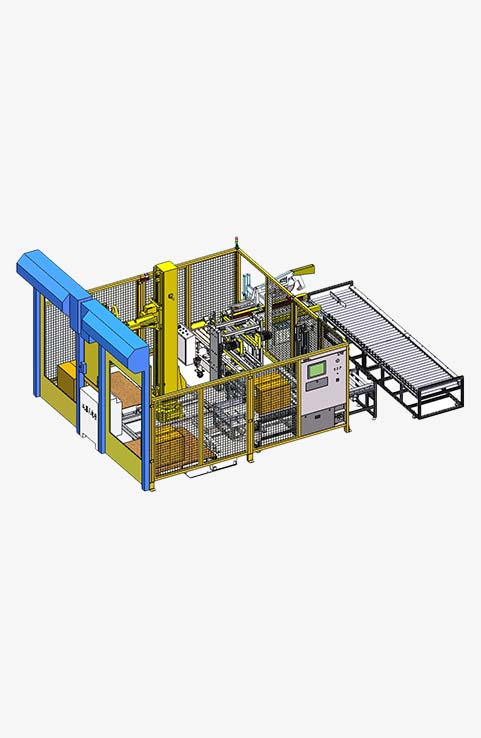

1 sealing and palletizing machine can correspond to 2 packaging lines

Two types of products can mix and flow into the sealing and palletizing machine

The equipment automatically recognizes the barcode of the outer box to distinguish which pallet it is placed on

Adaptive design, intelligent sensing of outer box size and automatic adjustment

The overall safety net enhances the safety of the equipment

Read barcode and upload MES

Support data exchange between production systems such as MES

Store at least 500 sets of product formulas